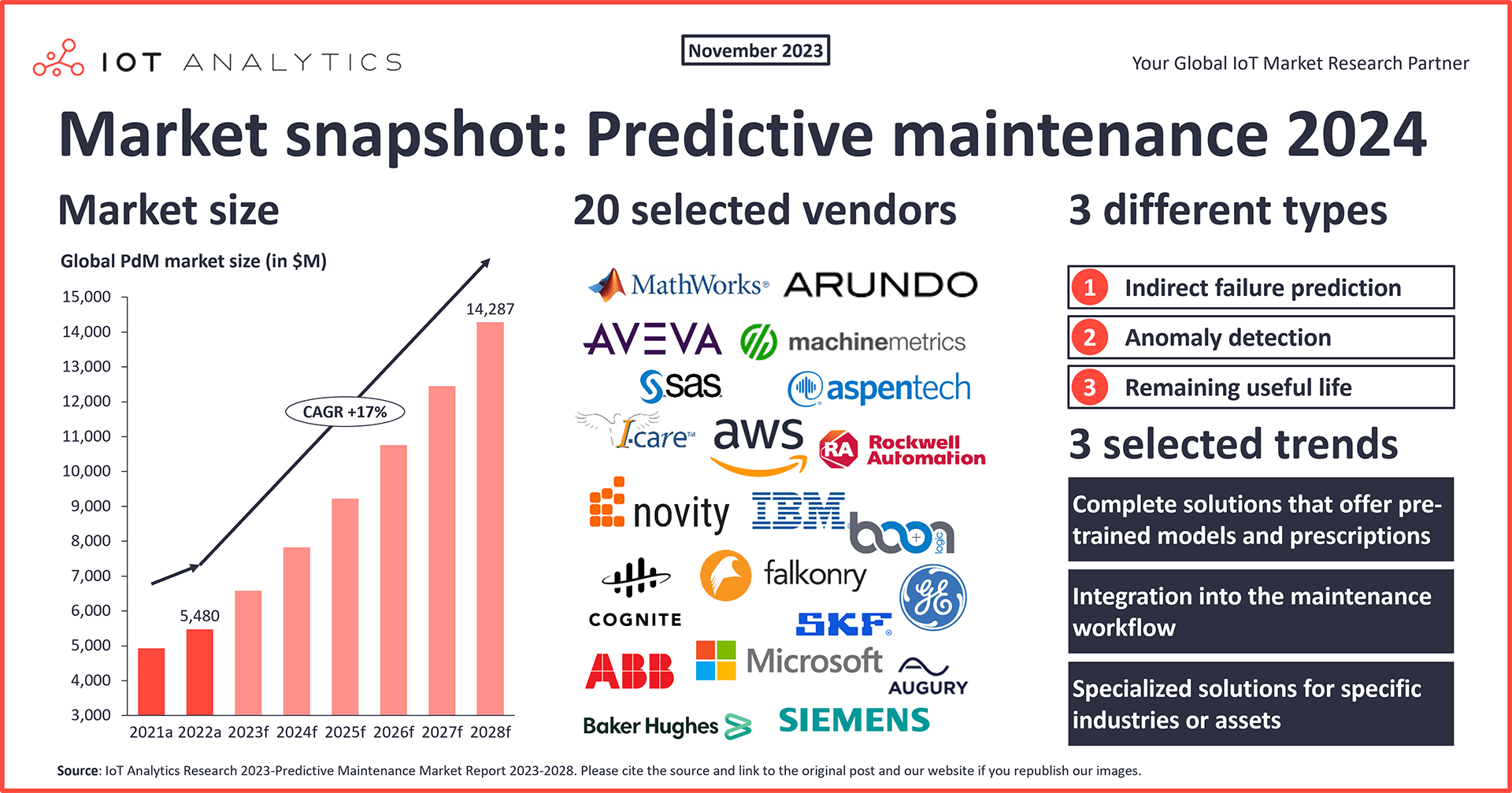

In the evolving landscape of fleet management, predictive maintenance (PdM) represents a sophisticated evolution beyond traditional approaches. Unlike preventive maintenance, which relies on fixed schedules regardless of the vehicle's actual condition, predictive maintenance leverages real-time data, sensors, and advanced analytics to forecast failures before they occur.

This data-driven strategy enables fleet operators to perform interventions precisely when needed, minimizing unplanned downtime and optimizing resource allocation.

Industry analyses indicate that predictive maintenance can reduce maintenance costs by 25-30%, increase vehicle availability by 20%, and significantly extend asset lifespans.

Understanding Predictive Maintenance in Fleet Operations

Predictive maintenance utilizes historical and real-time data from vehicle systems to predict when components are likely to fail. Key techniques include vibration analysis, oil condition monitoring, thermography, and ultrasonic testing, often integrated with telematics and IoT devices. Machine learning algorithms process this data to identify patterns indicative of impending issues, such as abnormal engine vibrations or irregular temperature fluctuations.

In contrast to the routine intervals of preventive maintenance, PdM uses condition-based triggers, ensuring maintenance is neither premature nor delayed. This approach has gained prominence with advances in AI and connectivity, enabling fleets to shift from reactive repairs to proactive foresight.

Core Techniques and Technologies

Several established techniques form the foundation of predictive maintenance programs:

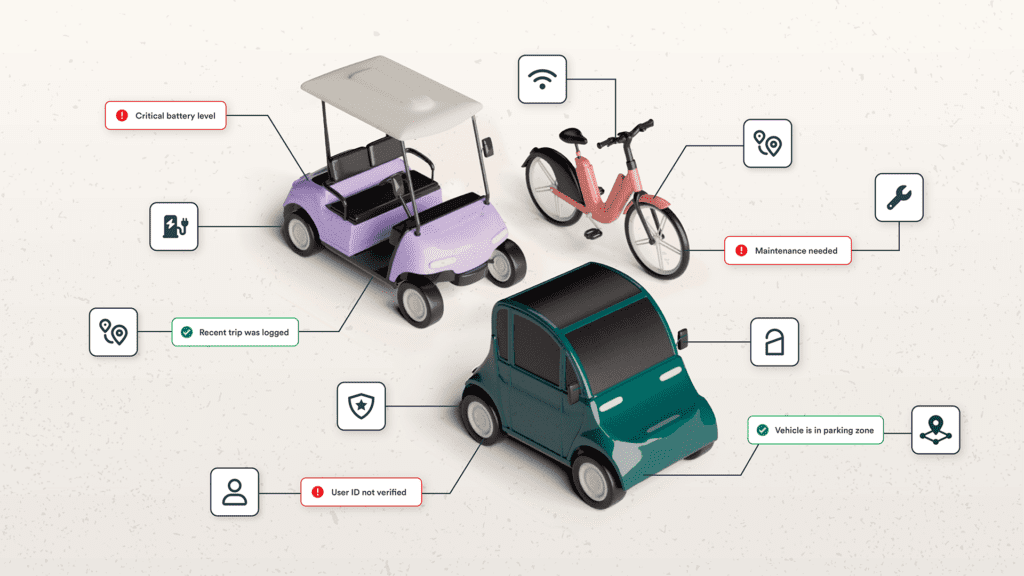

Sensor-Based Monitoring and Telematics

- IoT sensors track parameters like engine performance, brake wear, tire pressure, and fluid levels in real time.

- Telematics platforms aggregate data via GPS and onboard diagnostics, providing insights into usage patterns and health metrics.

Data Analytics and Machine Learning

- Algorithms analyze vast datasets to detect anomalies and predict the remaining useful life (RUL) of components.

- Predictive models incorporate factors such as mileage, driving conditions, and historical failure rates.

Vibration and Oil Analysis

- Vibration sensors identify imbalances or wear in moving parts, such as bearings or transmissions.

- Regular oil sampling reveals contaminants or degradation, signaling potential engine issues.

Dashboard Integration

- Centralized analytics dashboards visualize vehicle health scores, alerting managers to prioritized actions.

These techniques collectively enable up to 40% reductions in roadside breakdowns and substantial cost savings through targeted interventions.

Benefits for Fleet Management

Implementing predictive maintenance yields measurable advantages:

- Cost Reduction: By avoiding unnecessary repairs and emergency fixes, fleets can reduce maintenance expenses by 20-30%.

- Minimized Downtime: Early detection prevents disruptions, enhancing operational continuity and vehicle uptime.

- Extended Vehicle Lifespan: Proactive care addresses wear promptly, prolonging asset durability.

- Improved Safety and Compliance: Identifying risks early reduces accident potential and supports regulatory adherence.

These outcomes position PdM as a strategic tool for competitive fleet operations in 2025 and beyond.

Conclusion

Predictive maintenance techniques enable fleet managers to shift from scheduled maintenance to intelligent, condition-based strategies, improving efficiency and reliability.

At Wilmar Inc., we provide comprehensive fleet solutions, including leasing, analysis, and support for integrating advanced maintenance technologies. Our expertise can help you adopt predictive approaches tailored to your operations. Contact our team for consultation on enhancing your fleet's performance through data-driven maintenance.